Ferrous Alloys

Product Details:

- Strength Superior

- Purity 95% minimum

- Hardness High

- Product Type Alloy

- Material Iron with other elements

- Alloy Ferrous Alloy

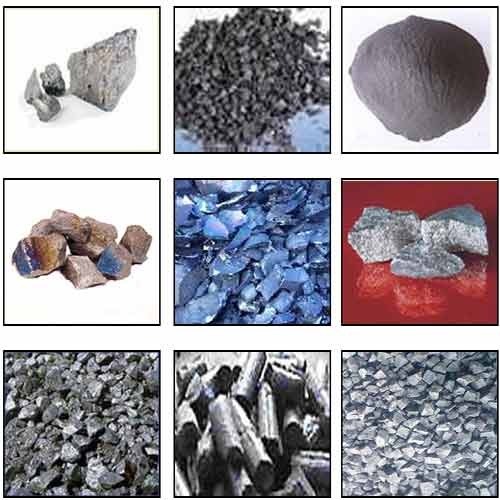

- Shape Lump, Powder, or As Required

- Click to view more

X

Ferrous Alloys Price And Quantity

- 500 Kilograms

Ferrous Alloys Product Specifications

- Ferrous Alloy

- Fe, C, Si, Mn and trace elements

- Nil

- Grey

- Lump, Powder, or As Required

- Customized

- Alloy

- Superior

- 95% minimum

- Steel production, Foundry, Metallurgical industries

- Iron with other elements

- High

Ferrous Alloys Trade Information

- Cash in Advance (CID)

- Yes

- Contact us for information regarding our sample policy

- Standard Packing

- North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Australia, South America, Asia

- All India

Product Description

Leveraging on expanded networking web and ethical business dealings, we are engaged in manufacturing and exporting Ferrous Alloys. These alloys are manufactured under the strict guidance of our experts using tested quality materials. Find usage in construction, automobile and engineering industries, these alloys are provided to our clients at feasible prices. These Ferrous Alloys are corrosion resistant and demanded among our clients due to their light weight and toughness. Clients can get these alloys from us at feasible prices.

Further Details:

- Nickel Cathodes

- Tin Ingot

- Copper Cathode

- Silicon Metal Lumps

- Magnesium Metal Ingots

- Manganese Metal Flakes

- Low Carbon Ferro Chrome

- Ferro Silico Magnesium

- Ferro Moly

- Ferro Silicon

- Graphite Powder

- Graphite Flakes

Superior Quality & Customization

Manufactured to rigorous metallurgical standards, our ferrous alloys deliver consistent strength and purity. With customizable dimensions, shapes, and finishes, they cater to a variety of industrial requirements. Packaging options include HDPE bags, drums, or other client-specified solutions, ensuring safe and efficient delivery every time.

Diverse Industrial Applications

Used extensively in steel production, foundries, and metallurgical operations, these alloys enhance performance and durability in end products. Their high hardness and exceptional properties make them indispensable for manufacturers looking for reliable, high-grade input materials in demanding applications.

Reliable Partnerships Across India

As a leading distributor, exporter, manufacturer, and supplier, we fulfill high-volume orders and adapt to unique customer requirements. Seamless logistics and quality control guarantee timely deliveries and consistent quality, supporting the ongoing success of your industrial operations.

FAQs of Ferrous Alloys:

Q: How are ferrous alloys with a density of 7.6 7.8 g/cm used in steel production?

A: These alloys are essential additives in steel manufacturing, improving the hardness, strength, and overall performance of steel products. Their specific composition ensures consistency and quality in metallurgical processes.Q: What packaging options are available for these ferrous alloys?

A: We offer a range of packaging solutions, including HDPE bags, drums, or customized options as per your requirements. This ensures product safety during transportation and storage.Q: When should I choose a custom finished alloy over an as-cast finish?

A: Custom finished alloys are ideal when precise shapes, dimensions, or surface quality are needed to fit specific processing or application settings, compared to as-cast, which is suitable for standard use.Q: Where can these ferrous alloys be supplied from and to?

A: We are based in India and export or supply domestically and internationally, catering to customers such as distributors, manufacturers, and metallurgical industries that demand high-quality ferrous alloys.Q: What is the process involved in manufacturing these metallurgical-grade ferrous alloys?

A: The process involves carefully controlled melting of iron and other elements like carbon, silicon, and manganese. Alloys are then cast or finished according to customer specifications to achieve desired properties.Q: How do these alloys benefit my production processes?

A: Their high purity, strength, and hardness enhance the durability and structural integrity of steel, leading to improved performance, reduced defects, and greater production efficiency.Q: Can I request specific dimensions, shapes, or moisture levels when ordering?

A: Absolutely, we accommodate custom requests for dimensions, shapes (lump, powder, etc.), and ensure all products are delivered moisture-free, meeting rigorous industrial standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free